The underwater granulator is similar to the airflow gra […]

The underwater granulator is similar to the airflow granulator and the water jet granulator. The equipment part mainly covers: plastic granulator, single and twin screw plastic extruder, plastic film blowing machine, bag making machine, printing machine, coating Machine, tape machine, tape slitting machine, slitting machine, strapping machine. The modified formula is mainly based on alloy materials, especially PET, PC, ABS, (PP, PA), which are currently growing in application areas; plastic formulas have developed cling film, degradable film, PET thickening and toughening formulas . The difference is that it has a steady stream of water flowing through the mold surface, and it is in direct contact with the mold surface. The size of the pelletizing chamber is just enough to allow the pelletizing knife to rotate freely across the die surface without restricting the temperature of the water flow. The molten polymer is extruded from the die, and the pellets are cut by the rotating knife. The pellets are taken out of the pelletizing chamber by the temperature-regulated water and enter the centrifugal dryer. In the dryer, the water is drained back to the storage tank, cooled and recycled for reuse; the pellets are passed through a centrifugal dryer to remove water.

The strip production line is inexpensive, easy to operate, and easy to clean. This has its advantages for color compounding, because the equipment must be thoroughly cleaned for the replacement of two batches of different color materials. However, the disadvantage of the method of making rods is that the cooling section takes up space, and its length is determined according to the temperature requirements of the polymer.

Before being made into final products, most polymers must be compounded and mixed and then pelletized to become marketable raw materials. The power required by the pelletizer is directly proportional to the extrusion volume and exponentially related to the size of the filter screen. There are many different pelletizer designs, but all pelletizers can be divided into two categories: cold pelletizing system and die face hot pelletizing system. The main difference between the two is the time arrangement of the pelletizing process. The cold pelletizing system cuts pellets from the solidified polymer at the end of the process; while in the die-face hot pelletizing system, pellets are cut when the molten polymer emerges from the die, and pellets are processed downstream cool down. Both types of pelletizing systems have their own advantages and disadvantages.

Cold pelletizing system: The cold pelletizing system includes a die, a cooling zone (air-cooled or water-cooled), a drying zone (if water-cooled) and a pelletizing chamber. There are two types of cold pelletizing systems, namely flake pelletizers and strip pelletizers.

The molten polymer is extruded from the hot die and cut into pellets by a rotating knife rotating on the surface of the die. The characteristic of this sweet grain system is its specially designed water jet cutting chamber. The water flows spirally around the cause until it flows out of the sweet grain chamber. After the pellets are cut, they are thrown into the water stream for preliminary quenching. The pellet water slurry is discharged into the pellet slurry tank to be further cooled, and then sent to a centrifugal dryer to remove water.

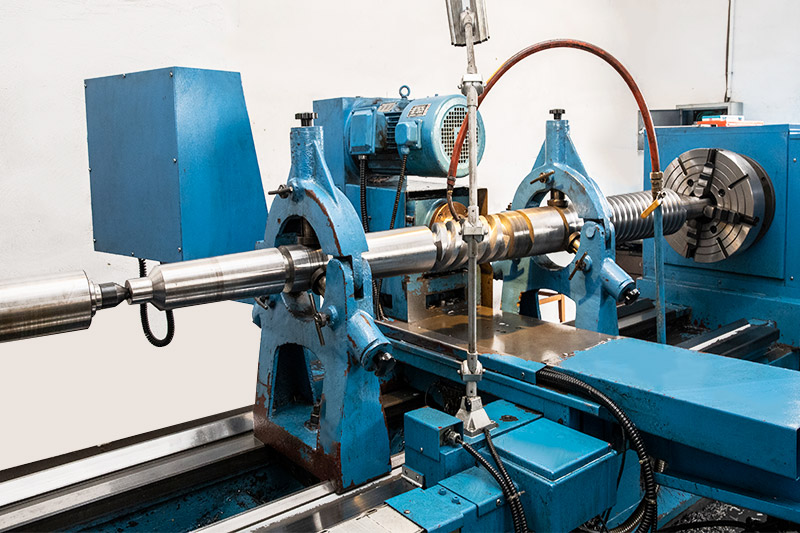

The use history of strip pelletizers is almost as long as that of tablet pelletizers. Including die, cooling section (water bath or blower), drying section (if water cooling is used) and pelletizing knife. Use an extruder or gear pump to extrude the molten polymer through a horizontally installed die to form a strip (modern die is precisely machined and heated uniformly to produce a stable quality strip). After the strip is discharged from the mouth, it is cooled by a blower or air/vacuum facility, or cooled by a water bath. If water cooling is used, the strips need to pass through a drying section, with forced ventilation to blow off the moisture, and then the strips are sent to the cutting room. Using the shearing action of a pair of fixed knives and rotating knives, the strip is accurately cut to the required length.